Lathe boring bar with vibration damper – how does it work and what are its characteristics?

The scope of activities of lathe knives is very wide and it is impossible to characterize them all in one blog text. That’s why in this entry we would like to tell you a little about turning knives for boring, i.e. the so-called boring bars. What are the characteristics of a lathe boring bar with a vibration damper and what is it used for? We invite you to read!

Characteristics and applications

Lathe boring bars are used for internal machining of materials. What stands out in their construction is the cylindrical shaft, which has flats at the very end for installation in a holder in a CNC lathe. The simplest knives in design are made of solid steel with a brazed plate or in a folding version with a replaceable cutting plate.

Of course, folding knives are better in design and have greater possibilities. This is not only about the durability of such a solution and the replacement of the tiles themselves. Knives with a monolithic body and a brazed plate are characterized by maximum 3D boring capabilities. What does it mean? Their reach during operation is three times their diameter. If the diameter of the cylindrical shank is, for example, 2 cm, the overhang is 6 cm. Above this length the knife starts to vibrate. Assuming that everything to be processed has been selected correctly and when such a knife is pulled out of the holder beyond the 3D length, the knife will vibrate, work less efficiently and with lower accuracy.

Going a step further, combined knives with a body made of sintered carbide were invented. About 80-90% of the grip is made of VHM and the soldered tip is steel. First of all, this material is characterized by higher hardness and stiffness, which means that the knives do not vibrate so quickly. This solution is sufficient for a boring depth of 5D and is called passively damped cutters. There is no structure inside the body that additionally dampens vibrations.

Lathe knife technology with vibration damper

The high availability of boring bars with 3D and 5D vibration damping structures has forced companies to develop technology and look for better and better solutions. Knives with active damping are distinguished from previous designs by a vibration damping system built inside. Such a system is made of a silencer, i.e. a material with high density and high mass. The damper is placed inside the boring bar and, to put it simply, works on the principle of a weight suspended on rubber. Depending on the size of the structure, such knives work to a boring depth starting from 7D.

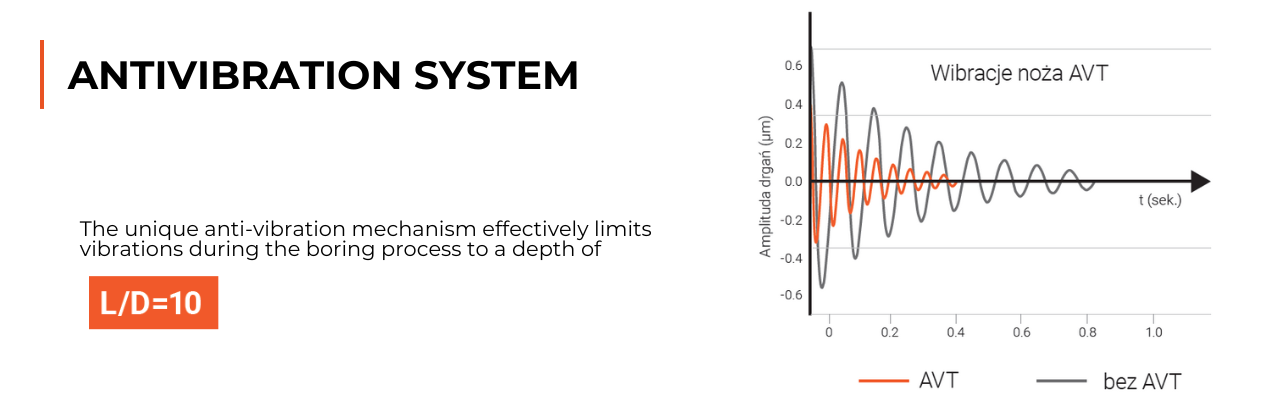

Available market solutions and the high know-how of our designers prompted us to develop our own design of a lathe boring bar with vibration damping. In this way, we have created the Humm Vibra series knives, whose unique anti-vibration mechanism effectively eliminates vibrations during the boring process to a depth of L/D = 10. Additionally, thanks to the effective reduction of vibration, we managed to significantly shorten the cutting time.

The Humm Vibra vibration-damped lathe boring bar has its own patented assembly system of replaceable boring heads. No one on the market has a similar solution in this aspect. Despite its compact structure, the handle allows you to carry heavy loads and effectively dampen vibrations. Importantly, vibrations do not affect our assembly system in any way. Moreover, the replaceable heads in Humm Vibra do not limit the shape of the working part.

We encourage you to familiarize yourself with the offer of vibration-damped lathe boring bars from the Humm Vibra line, available from JG Precision Tools.