How do Humm Clamp 5-axis vises work? See the videos

HUMM CLAMP vices and their brief characteristics

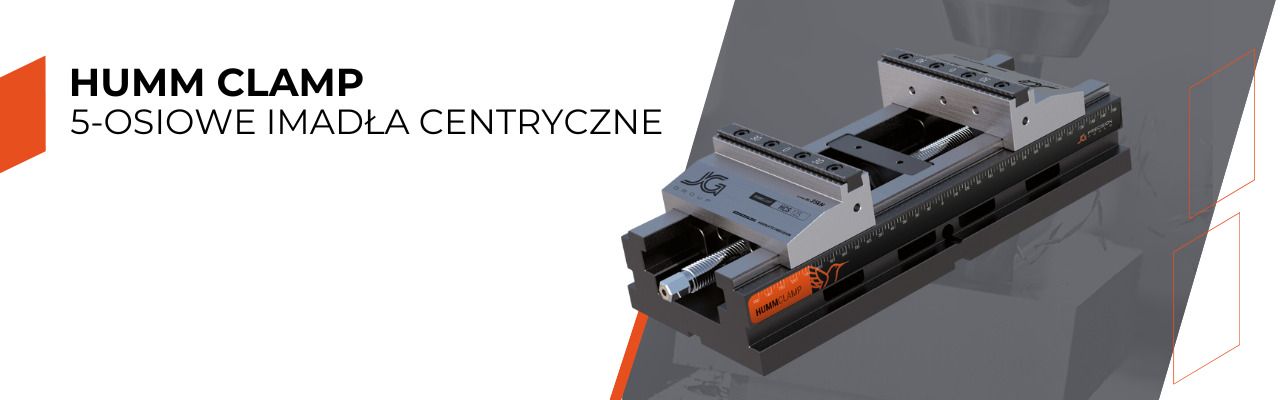

HUMM CLAMP clamping systems are vises adapted to work in 5-axis machining. One of their most distinguishing features is their modular structure. Our non-standard approach to the use of vises allows our customers to purchase selected elements without the need to order the entire set. Separate purchase of jaws and replaceable tooth inserts is definitely financially more beneficial for each customer when, due to human error, only one part of the vice is damaged and the rest is fully functional.

Their next important advantage is the high clamping force, exceeding 35 kN. What does this mean in practice? We have eliminated the need to prepare the cube curve in advance for processing. With such high force, the clamp in the teeth ensures stability of processing, with the risk of tearing the detail from the cube reduced to a minimum.

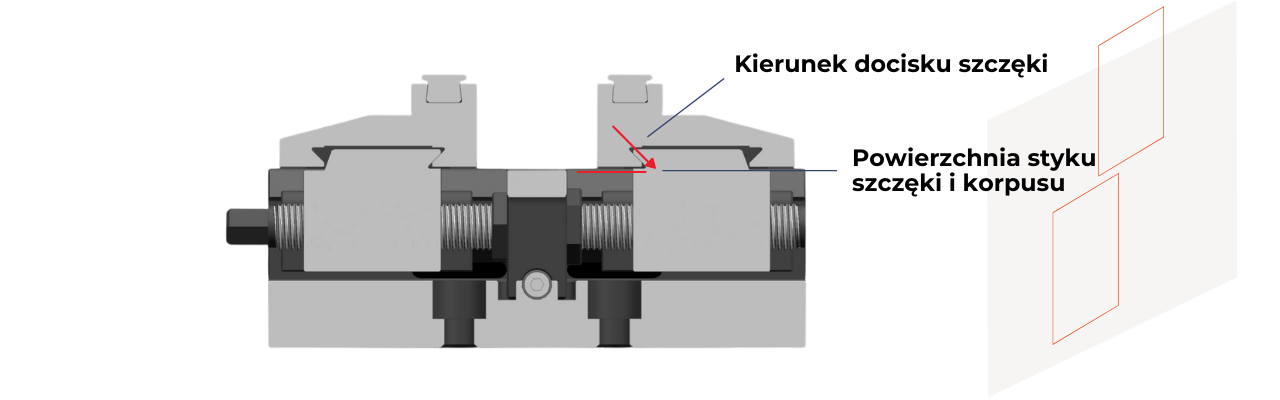

HUMM vises are characterized by one more important feature. Ease and speed of changeover. Replacing the jaws takes several seconds, and the operator does not need any tool to replace them. The jaws are mounted on the so-called dovetail.

How do our 5-axis vises perform?

Ignorance about our product may potentially raise doubts in you. Will HUMM CLAMP vises really work in my case? Lack of screw assembly may cause the jaws to lift or weaken the ankle clamp in the jaws. To dispel any potential doubts, we invite you to watch videos of the operation of HUMM CLAMP vises. Take a look and see if our clamping system is for you.

If you are interested in the exact specifications of our vise sets or their individual components, we strongly encourage you to visit the “5-axis centric vices” tab on the JG Precision Tools website. For more information, please visit our office or contact us by phone or e-mail.

📧 biuro@jg-group.pl | ☎️ +48 81 468 00 30