Need help or have additional questions?

Text me. I will be happy to advise you on selecting the right tools for your company and present opportunities for joint cooperation.

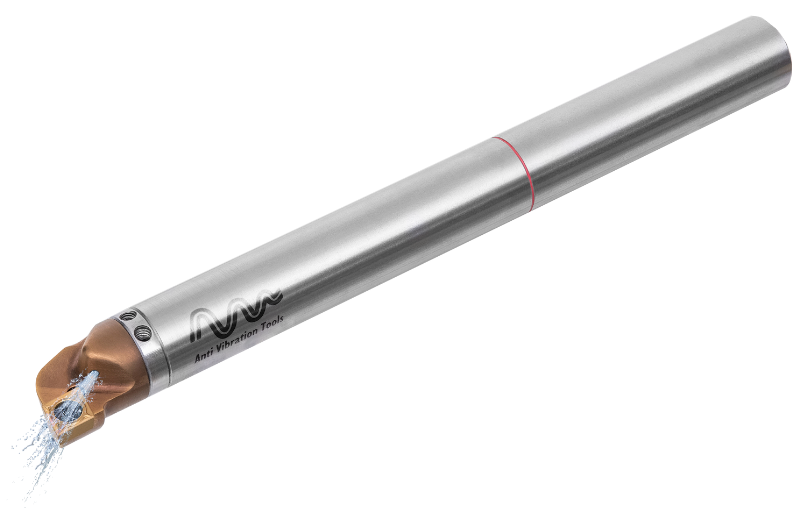

HUMM VIBRA antivibration tools have been developed and patented by our company. Their unique anti-vibration mechanism effectively reduces vibration during the boring process to a depth of L/D=10. With efficient vibration reduction, it significantly reduces cutting time.

In addition, HUMM VIBRA tools feature easy head change. We have developed a simple and very quick-to-use system for changing them. HUMM VIBRA have a precise system of direct coolant supply to the cutting zone, which allows for longer and more efficient operation. It thus guarantees increased durability of cermet inserts.

CHECK OUT VIDEO

No problem! Take a look at our catalog prepared as a PDF file.

DOWNLOAD OUR CATALOGUE

Unique head mounting mechanism

The Humm Vibra vibration-damped lathe boring bar has its own patented assembly system of replaceable boring heads. No one on the market has a similar solution in this aspect. Despite its compact structure, the handle allows you to carry heavy loads and effectively dampen vibrations.

Profiled shape of the working part

The replaceable heads in Humm Vibra do not limit the shape of the working part. Importantly, vibrations do not affect the head assembly system in any way.

Efficient cooling system

Humm Vibra lathe boring bars are equipped with an internal cooling system directed directly at the cutting insert.

Shorter boring time

A unique vibration damping mechanism that limits vibrations at the maximum tool reach L/D=10 ensures a stable and, most importantly, fast machining process. Additionally, chip evacuation from the cutting zone is very good.

Text me. I will be happy to advise you on selecting the right tools for your company and present opportunities for joint cooperation.